Rapid Prototyping for Metal and Plastic Parts Processing

In the development of metal and plastic products, rapid prototyping serves as a bridge between design and mass production. By quickly creating physical prototypes, companies can:

Verify design feasibility: Test structure, assembly, and functionality early.

Shorten development cycles: Reduce from weeks to days, accelerating time-to-market.

Lower development costs: Minimize mold modification risks and avoid rework during production.

Improve client communication: Provide tangible samples for confirmation, reducing misunderstandings.

Technologies & Processes

A. For Metal Parts:

CNC Machining: Ideal for aluminum, steel, brass. Offers high precision, real material properties. Best for functional, load-bearing, high-tolerance parts.

Laser Cutting & Bending: For sheet metal prototypes (enclosures, brackets). Fast and cost-effective.

Metal 3D Printing (SLM/DMLS): For complex, lightweight designs (lattice structures, internal channels) in stainless steel, titanium, or aluminum.

B. For Plastic Parts:

CNC Machining (Plastics): Uses ABS, PC, Nylon, POM. Provides true material performance for stress testing.

3D Printing:

SLA/DLP: High surface finish, fine details. Perfect for appearance models, clear parts.

SLS: Nylon-based, no supports needed. Great for snap-fits, hinges, functional assemblies.

FDM: Lowest cost, fast. Suitable for conceptual models, large simple parts.

Vacuum Casting (Urethane Casting): Uses silicone molds to produce 10-100 parts in various colors/material properties. Ideal for pre-production runs, user testing.

Application-Based Selection Guide

Match the technology to the need:

"I just need to see and feel the shape" → SLA 3D Printing or CNC + Painting.

"I need to test gear strength and wear" → POM CNC or Nylon SLS.

"I must verify metal-to-plastic assembly" → Aluminum/Steel CNC + Plastic CNC or SLS.

"I need 50 units for a trade show" → Vacuum Casting.

"My design has impossible internal metal geometry" → Metal 3D Printing.

Standard Workflow

1. Requirement Analysis: Define purpose, material, quantity, budget, timeline.

2. Design for Manufacturability (DFM) Review: Optimize design for prototyping and future production.

3. Process Selection & Quotation: Recommend the best technical solution.

4. Data Preparation: Submit 3D files (STEP/IGS), finalize details.

5. Production & Post-Processing: Machining/printing, plus finishing (sanding, painting, anodizing, plating).

6. QC & Delivery: Provide inspection report (critical dimensions) and physical samples.

Metal Rapid Prototyping Technologies

CNC Machining (Metal)

Suitable Materials: Aluminum alloys, Stainless steel, Copper, Titanium alloys, Tool steel

Technical Features:

Accuracy up to ±0.025-0.1mm

Material properties identical to final product

Excellent surface quality, suitable for various surface treatments

Typical Applications:

Mechanical structural parts, connectors

Housings, brackets, bases

Precision transmission components

Advantages: High precision, real materials, high strength

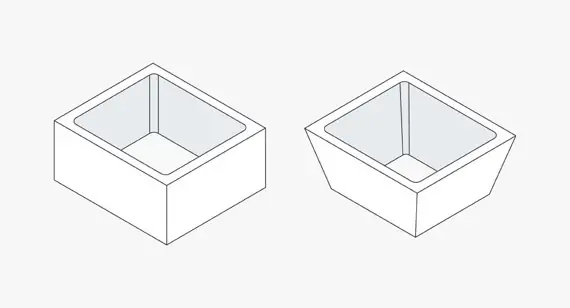

Limitations: Limited ability for complex internal structures, significant material waste

Sheet Metal Laser Prototyping

Process Combination: Laser cutting + CNC bending + Welding

Technical Features:

Rapid prototyping of thin-walled metal structures

High cost-effectiveness

Capable of producing large sheet metal parts

Typical Applications: Enclosures, cabinets, housings, brackets, protective covers

Metal 3D Printing

Main Technologies: SLM (Selective Laser Melting), DMLS (Direct Metal Laser Sintering)

Materials: Stainless steel, Aluminum alloys, Titanium alloys, Tool steel, Cobalt-chrome alloys

Unique Advantages:

Manufacture complex geometries impossible with traditional methods

Integrated forming, reducing assembly needs

Enable lightweight designs

Application Scenarios: Complex cooling channels, lightweight structures, customized implants, mold inserts

Get A QoutePlastic Rapid Prototyping Technologies

CNC Plastic Machining

Suitable Materials: ABS, PC, PMMA, Nylon, POM, PEEK

Advantages:

Uses real engineering plastics, reliable performance

High precision, suitable for precision fitting parts

Good surface finish

Applications: Gears, bearings, housings, transparent windows, high-load test parts

Vacuum Casting (Silicone Molding)

Process: Create master pattern → Make silicone mold → Cast polyurethane resin

Material Options: ABS-like, PP-like, PC-like, transparent, flexible resins

Core Value:

Rapid small-batch production (10-500 pieces)

Multiple material hardness options

Cost significantly lower than steel mold tooling

Typical Applications: Market testing, crowdfunding samples, exhibition prototypes, small batch sales

3D Printing Technologies

SLA/DLP

Material Options:Various photosensitive resins; Accuracy: High (±0.1mm); Strength: Medium ; Surface Quality: Excellent, comparable to injection molding

SLS

Material Options:Nylon (PA), Glass-filled nylon; Accuracy:Medium (±0.15mm); Strength: High, close to injection molding ; Surface Quality: Slightly rough, can be post-processed

FDM

Material Options:Various photosensitive resins; Accuracy: Lower (±0.2mm); Strength: Medium ; Surface Quality: Visible layer lines

PolyJet

Material Options:ABS-like resins, Flexible materials; Accuracy: Very high (±0.1mm); Strength: Medium ; Surface Quality: Excellent, smooth and detailed

Rapid Prototyping Process Selection Decision Guide

I. Core Decision Dimensions

When quickly selecting a process, focus on these 5 key dimensions:

Accuracy Requirement (Within ±0.1mm?)

Material Authenticity (Need real engineering materials?)

Lead Time (How fast do you need it?)

Budget Constraint (How much can you spend?)

Prototype Purpose (Appearance showcase / Functional testing / Small batch?)

II. Quick Selection Guide

Ask yourself these three key questions:

Question 1: What is it for?

Just to see the look → Choose SLA (best surface finish)

To test function/strength → Choose CNC Machining or SLS Nylon Printing (realistic materials)

Need 10-100 samples → Choose Vacuum Casting (lowest cost per part)

Extremely complex geometry → Choose 3D Printing (SLA/SLS)

Question 2: Does the material matter?

Must use real metal/plastic → Must choose CNC Machining

Simulation is acceptable → Can choose 3D Printing or Vacuum Casting

Question 3: What’s the timeline and budget?

Need it tomorrow, low budget → FDM or SLA 3D Printing

Within 3 days, medium budget → CNC Machining

~1 week, need multiple copies → Vacuum Casting

Get A QouteTechnical and Economic Analysis

1.1 Cost Structure Comparison

3D Printing: Main cost = Material + Machine time, suitable for complex geometries

CNC Machining: Main cost = Programming + Machining time + Material waste, suitable for high-precision simple geometries

Vacuum Casting: Main cost = Mold cost + Per-part material cost, suitable for small batches (10+ pieces)

1.2 Time Efficiency Analysis

Fastest: Simple 3D printing (several hours)

Most Common: CNC (1-3 days)

Small Batches: Vacuum casting (3-7 days)

Successful Application Cases

Case 1: Smart Lock Development

Challenge: Verify assembly between metal lock body and plastic housing, and electronic component layout

Solution:

Lock body: Aluminum CNC machining + Anodizing

Housing: SLA printing + Painting

Internal brackets: Sheet metal laser forming

Result: Identified 3 assembly interferences in advance, saved ¥150,000 in mold modification costs

Case 2: Medical Handheld Device

Challenge: Ergonomic testing and sterilization validation

Solution:

Main body: SLS nylon printing (heat-resistant for sterilization)

Buttons: SLA transparent resin (verify internal lighting effects)

Seals: Silicone casting

Result: Optimized grip angle, passed actual sterilization testing

Case 3: Industrial Robot End Effector

Challenge: Balance lightweight design with high strength

Solution:

Main structure: Titanium metal 3D printing (topology optimized design)

Connectors: Stainless steel CNC machining

Get A Qoute

Best Practices and Recommendations

1.1 Design Optimization Suggestions

Design for Rapid Prototyping:

CNC: Consider tool accessibility, avoid deep and narrow cavities

3D Printing: Optimize support structures, consider print orientation effect on strength

Vacuum Casting: Include draft angles, reserve gate locations

File Preparation Standards:

Provide 3D files in STEP or IGES format

Indicate critical dimensions and tolerance requirements

Specify surface treatment needs clearly

1.2 Supplier Selection Criteria

Technical Capability: Possession of multiple process technologies

Quality System: Established inspection procedures

Design Support: Ability to provide professional DFM advice

NDA/Confidentiality: Emphasis on intellectual property protection

1.3 Development Trends

Hybrid Manufacturing: Combined 3D printing and CNC processing

New Material Development: Higher-performance rapid prototyping materials

Digital Services: Online quoting, real-time production tracking

Automated Post-processing: Robotic polishing, automated painting

Conclusion

Rapid prototyping technologies for metal and plastic provide unprecedented flexibility in product development.

Correct selection and application of these technologies can:

Shorten product development time by 50-70%

Reduce development costs by 30-50%

Significantly increase first-time mold success rate

Accelerate innovation cycles, enhance market competitiveness