Mass Production Solution for Hardware and Plastic Components

Mass production in metal and plastic processing is a highly systematic endeavor built on a foundation of tooling (molds), structured around automated assembly lines, and sustained by rigorous process control. Its success hinges on upfront DFM and mold investment, coupled with the relentless pursuit of efficiency, cost, and quality during production.

I. Core Processing Technologies

1. Hardware Processing Section

Stamping: The absolute core of mass production. Uses dies and presses to punch, bend, draw, and form metal sheets. Extremely fast (up to hundreds of strokes per minute), low cost, and high consistency. Suitable for chassis, brackets, connectors, enclosures, etc.

Die Casting: Involves injecting molten metal (e.g., aluminum, zinc alloy) under high pressure into a steel mold for rapid shaping. Ideal for complex, precise, high-strength metal parts like gears, hardware fittings, and automotive components.

CNC Machining: In mass production, used primarily for mold manufacturing and high-precision secondary machining (e.g., drilling, milling slots after stamping/die casting). Fully CNC machining individual parts is not suitable for true ultra-high-volume production.

Others: Processes like fastener manufacturing (cold heading) and powder metallurgy are also commonly used for mass-producing specific parts.

2. Plastic Processing Section

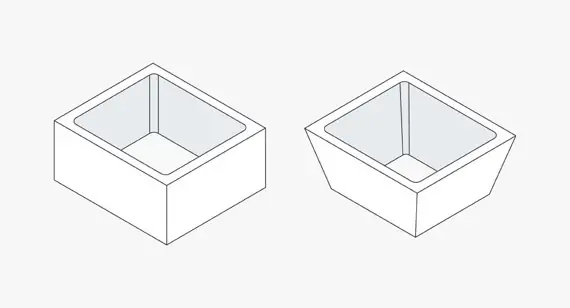

Injection Molding: The absolute core of plastic mass production. Heats plastic pellets until molten, then injects them under high pressure into a steel mold cavity. After cooling, the part is ejected. Extremely efficient, capable of producing parts with highly complex shapes. Suitable for housings, buttons, containers, precision components, etc.

Blow Molding: Mainly used for producing hollow items like bottles and containers.

Extrusion: Produces continuous profiles with constant cross-sections, such as pipes, rods, and sheets.

3. Secondary Processing and Surface Treatment

These are critical steps for enhancing product functionality and aesthetics, often also performed on automated assembly lines.

Hardware: Plating (nickel, chrome, zinc), painting (powder coating, spray painting), anodizing (for aluminum), brushing, polishing, etc.

Plastics: Painting, UV coating, plating (electroplating, vacuum metallization), screen printing, pad printing, laser engraving, etc.

Assembly: Automated assembly lines, robotic arms, ultrasonic welding, heat staking, automatic screwdriving, etc., are used to assemble hardware and plastic parts into final products.

II. Key Considerations for Mass Production

1. Design and Tooling (Molds)

DFM (Design for Manufacturability): This is the most critical first step. Designers must work closely with engineers to ensure the product design facilitates mold manufacturing, material flow, part ejection, and assembly to reduce costs and defect rates.

Molds/Tooling: Molds represent the core high one-time investment. Mass production uses high-hardness, long-life precision steel molds (e.g., injection molds, stamping dies). Mold quality directly determines product quality, production efficiency, and lifecycle cost.

2. Material Selection

Hardware: Cold-rolled steel, stainless steel, aluminum, copper, zinc alloys, etc., considering strength, toughness, corrosion resistance, and cost.

Plastics: ABS, PC, PP, PA (Nylon), POM (Acetal), etc., considering mechanical properties, temperature resistance, flame retardancy, appearance (e.g., transparency), and price. Custom color masterbatches are often used for color consistency.

3. Production and Quality Control

Automation and Assembly Lines: High automation is fundamental to ensuring output, reducing costs, and maintaining consistent quality. Includes automatic feeders, robotic part removal, conveyor systems, etc.

Process Control: Strict monitoring of key process parameters (e.g., temperature, pressure, time in injection molding; tonnage, speed in stamping).

Quality Inspection: Implementation of Statistical Process Control (SPC). Methods include: First Article Inspection, patrol inspections, full dimensional checks (using CMM), functional testing, durability testing. Extensive use of gauges, jigs, and Automated Optical Inspection (AOI).

4. Supply Chain and Logistics

Stable raw material supply, efficient inventory management (e.g., Just-In-Time production), and a robust finished goods distribution network are crucial for mass production.

III. Advantages and Challenges

Advantages:

Economies of Scale: Unit cost decreases significantly as production volume increases.

High Efficiency and Consistency: Automated lines can operate 24/7, producing products with highly uniform quality.

High Production Capacity: Can meet massive global market demand.

High Degree of Technological Integration: Facilitates the integration of advanced technologies and processes.

Challenges:

Very High Initial Investment: Costs for molds, dedicated equipment, and production line setup are extremely high.

Lack of Flexibility: Once a line is set up, changing the product or design is very difficult and costly.

High Minimum Order Quantity (MOQ) Requirements: Requires very large orders to amortize the high upfront costs.

Inventory Risk: Forecasting errors can lead to large inventories of finished or semi-finished goods.

High Dependence on Tooling: Any issues with the molds can halt the entire production line, causing significant losses.a

Two Pillars and Foundations on Running Through the Mass Production

1. Final Confirmation and Optimization of Molds and Tooling

Mold Acceptance (After T0 Trial): It’s not enough for a mold to simply make a part. It must be validated based on data from pilot production runs (e.g., T1-T3) to ensure stability, longevity, ease of maintenance, cooling efficiency, venting, etc., under continuous production. The mold must be in a true mass-production-ready state.

Full Lifecycle Management: Establish a preventive maintenance schedule for the molds, specifying servicing intervals after a certain number of cycles.

Dedicated Gauges and Fixtures: Design and manufacture fast, accurate dedicated inspection gauges (GO/NO GO gauges) and assembly/testing fixtures based on the product’s critical dimensions and assembly requirements. These are crucial for ensuring the speed and consistency of in-line inspection.

2. Solidification of Production Processes and Process Parameters

Standard Operating Procedures (SOPs): Create illustrated SOPs for every key station (e.g., machine startup, material loading, part removal, patrol inspection) as the sole standard for operators.

Locking Down Process Parameter Windows: Determine the optimal process parameters (e.g., temperature, pressure, time, speed for injection molding; tonnage, stroke, speed for stamping) through pilot runs and define their safe upper and lower limits. Input these parameters into the equipment and lock access to prevent unauthorized changes.

Work Instructions (WIs): Cover all processes in detail, including standards for post-processing (painting, printing), assembly, and packaging.

Get A QouteThree Controls on Running Through the Mass Production

1. Supply Chain and Material Control

Raw Material Batch Management: Require suppliers to provide material property sheets for each batch (e.g., MFI, hardness for plastics; material certs for metal) and conduct Incoming Quality Control (IQC). Ensure consistency across different material batches.

Sub-Supplier Management: Manage the quality and delivery of key purchased components (e.g., screws, springs, electronic parts).

Inventory and Logistics Planning: Establish safety stock levels and plan the flow and storage areas for raw materials, work-in-progress (WIP), and finished goods (e.g., FIFO - First In, First Out).

2. Production Floor and Process Control

First Article Inspection (FAI): Must be conducted comprehensively at the start of each shift, after mold or material changes, etc. The first pieces must be compared against master samples before production continues.

In-Process Quality Control (IPQC): At fixed frequencies (e.g., hourly), a specified number of products are sampled and inspected according to the standard, with key dimensions recorded on a Control Chart (X-R Chart) to monitor process stability and control in real-time.

Statistical Process Control (SPC): Perform statistical analysis on data from Critical-to-Quality characteristics to warn of trending changes, enabling preventive quality control rather than post-production inspection.

Equipment and Mold Checks: Operators and maintenance personnel perform regular checks and record the status of equipment and molds.

3. Final Quality and Outgoing Control

Outgoing Quality Control (OQC): Before finished products are packaged and stored, conduct sampling inspections according to the AQL standard. Only qualified batches can be released.

Standardized Packaging and Labeling: Design packaging solutions that protect products and facilitate transportation and storage. All cartons must have clear labels (part number, quantity, production date, lot/batch number).

Traceability System: Establish a complete traceability chain from raw material batch -> production date/shift -> finished goods batch number. This allows for rapid problem localization and recall if issues arise in the market.a

Get A Qoute

Four Preparations before the Mass Production

1. Personnel and Training Preparation

Clear Organizational Structure: Define clear roles and responsibilities for production, quality, engineering, and materials management positions.

Systematic Training: Train and assess all operators and inspectors on SOPs, WIs, safety, and quality awareness. Implement a "certified to operate" system.

2. Quality System Documentation Preparation

Quality Control Plan (QCP): This document defines all control points from incoming materials to outgoing shipment and is the overarching plan for quality activities.

Product Inspection Standards: Clearly define the line between acceptable and defective products with illustrations/photos. Limit Samples are highly recommended.

Non-Conforming Product Control Procedure: Clearly define the process for identifying, segregating, reviewing, and disposing of non-conforming products (rework, scrap, concession).

3. Capacity and Planning Preparation

Capacity Verification: Scientifically calculate daily/weekly/monthly capacity based on standard cycle times and Overall Equipment Effectiveness (OEE), serving as the basis for order acceptance and production scheduling.

Master Production Schedule (MPS): Develop a detailed production schedule (down to daily or weekly) based on orders and forecasts.

Production Kick-off Meeting: Convene a meeting with all relevant personnel (production, quality, engineering, materials, etc.) before the production start date to confirm all preparations are complete.

4. Risk Management and Contingency Preparation

Develop Contingency Plans: Establish response procedures and backup plans for situations like sudden equipment failure, critical material shortages, or emergent quality issues.

Establish a Rapid Response Team: Ensure production, engineering, and quality personnel can be on-site immediately to resolve problems.a