Materials We Supply

With the assistance of ANXIN’s team to advise on the optimal materials from our extensive range of metal and plastic options, available in various colors, infill densities, and hardness levels. All our materials are sourced from trusted suppliers and undergo rigorous inspection to ensure compatibility with diverse manufacturing processes, including CNC machining, die casting, plastic injection molding and sheet metal fabrication.

CNC Machining & Injection Molding Materials

CNC Machining Materials

Aluminum High strength-to-weight ratio

Stainless steel Good corrosion resistance + High Hardness

Steel Good machinability + Excellent electrical conductivity

Brass Good machinability + Excellent electrical conductivity

Copper >99.3% Purity + Superior electrical conductivity

Titanium Corrosion resistance + High tensile strength

ABS High stability + Easy to process

POM (Delrin) Low-friction + High-stiffness

PC (Polycarbonate) High impact resistance + High transparency

PA (Nylon) High chemical and heat resistance + High abrasion and wear resistance

PMMA (Acrylic) High transparency + Good chemical stability

PEEK High-performance thermoplastic, very high strength, thermal and chemical resistant.

PP (Polypropylene) Excellent chemical resistance. Food-safe grades available.

PE (Polyethylene) Excellent strength-to-weight ratio, impact and weather resistant.

Plastic Injection Molding Materials

ABS High stability + Easy to process

POM (Delrin) Low-friction + High-stiffness.

PC (Polycarbonate) High impact resistance + High transparency

PA (Nylon) High chemical and heat resistance + High abrasion and wear resistance

PMMA (Acrylic) High transparency + Good chemical stability

PEEK High-performance thermoplastic, very high strength, thermal and chemical resistant.

PP (Polypropylene) Excellent chemical resistance. Food-safe grades available.

PE (Polyethylene) Excellent strength-to-weight ratio, impact and weather resistant.

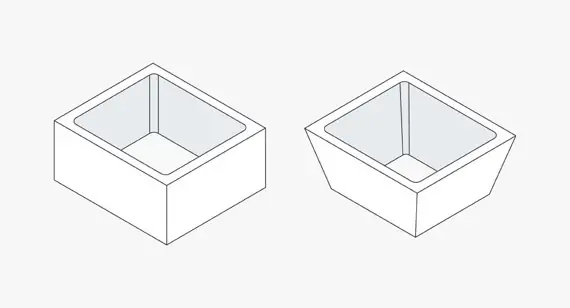

How do we select the suitable material for our products?

At ANXIN, we prioritize selecting industrial materials that are both cost-effective and meet your product’s functional and aesthetic requirements. Our focus is on ensuring your complete satisfaction without compromising on quality or cost. Our experienced procurement team, with more than ten years of expertise in sourcing from industrial material suppliers, has set material supply standards that exceed typical industry benchmarks. This includes biannual assessments of our suppliers to maintain our high standards.

Our approach to quality doesn’t stop there. Whether we’re dealing with plastics or metals, our dedicated quality inspection team conducts thorough testing of all incoming materials using our extensive range of in-house testing equipment. This encompasses detailed evaluations for corrosion, radiation, and other critical factors, using more than ten distinct testing methods.

You can be confident that, with ANXIN, the material selection for your product is in the most capable hands. We take full responsibility for ensuring the materials we use are of the highest standard, guaranteeing the excellence and reliability of your product.

Why Choose ANXIN as Your CNC Metal Machining Supplier?

As a CNC metal machining

manufacturer, ANXIN provide high-quality CNC metal parts and metal lathe

services.

Fast,Reliable Delivery

We understand time sensitive requirements of metal CNC services and react

quickly.

Rich Experience

We have decades of experience in metal lathe services for all industries and we

work with your project engineers to ensure understand of sheet CNC

requirements.

Design for machining metal parts

When you upload your 3D CAD file to request a quote, we’ll analyse your

part geometry to identify any features that may be difficult to CNC metal sheet

machine such as tall, thin walls or holes that cannot be threaded.