Wire Electrical Discharge Machining

Anxin Precision leverages advanced Wire Electrical Discharge Machining (WEDM) to craft high-precision components for aerospace, medical, electronic and automotive industries. Our WEDM process enables non-contact machining of hard, brittle materials and complex geometries, delivering micron-level accuracy and superior surface finish. Backed by OEM/ODM customization capabilities and cost-effective solutions, we turn your intricate design needs into reliable, high-quality parts.

ISO 9001:2015

How to Achieve Wire Electrical Discharge Machining (WEDM)?

1. Workpiece & Wire Electrode Setup

Secure the conductive workpiece on the WEDM machine table, and thread a thin, continuously moving wire electrode (typically brass or copper) through a pre-drilled start hole or along the target cutting path.

2. Parameter Configuration

Set critical machining parameters, including discharge voltage, current, wire feed rate, and dielectric fluid flow rate, based on the workpiece material (e.g., tungsten, steel) and desired precision.

3. Discharge & Cutting Execution

Immerse the workpiece and wire in dielectric fluid to cool the area and flush away debris; the machine generates controlled electrical sparks between the wire and workpiece to erode material, while the CNC system guides the wire to follow the programmed path for precise shaping.

4. Post-Machining Finishing

After the cutting process, remove the workpiece and perform cleaning and deburring to eliminate residual debris, ensuring the part meets the required surface finish and dimensional tolerance standards.

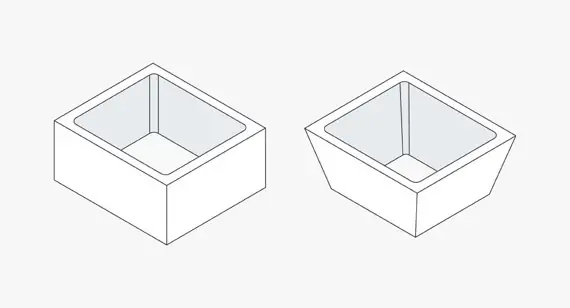

Structures of WEDM

1. Wire Electrode System: Consists of a thin conductive wire (brass/copper), wire spools, tensioners, and guides, ensuring stable, continuous wire movement during machining.

2. Workpiece Fixture & Table: A precision CNC-controlled table with clamps to secure the workpiece, enabling multi-axis positioning for complex cutting paths.

3. Dielectric Fluid Unit: Includes a reservoir, pump, and nozzles to circulate and spray dielectric fluid, cooling the machining zone and flushing away debris.

4. CNC Control Cabinet: The core control module that stores cutting programs, adjusts machining parameters, and drives the wire and table movements for high-precision shaping.

Principles of WEDM

1. Anxin Precision’s WEDM leverages thermal spark erosion to cut hard conductive materials with micron-level precision, no physical contact involved.

2. Our dielectric fluid system ensures efficient cooling and debris removal, delivering superior surface finish for complex components.

3. CNC-guided wire movement enables accurate shaping of intricate geometries, meeting the strictest tolerance demands of high-end manufacturing.

Key Advantages of WEDM Technology

1. Non-contact Machining

No direct physical contact between wire and workpiece eliminates tool wear and deformation, ideal for thin-walled or fragile components.

2. High Precision & Tolerance

Achieves micron-level accuracy and tight dimensional tolerances, capable of cutting intricate geometries like narrow slots and sharp corners.

3. Versatile Material Compatibility

Processes hard, conductive materials (e.g., tungsten, titanium, hardened steel) that are difficult to machine with conventional methods.

4. Superior Surface Finish

Minimizes post-processing needs with smooth surface quality, reducing burrs and residual stress on finished parts.

Classification of WEDM

1. By Machining Precision: Conventional WEDM & High-Precision WEDM

- Conventional WEDM is cost-effective for general industrial parts with moderate tolerance requirements, suitable for batch production of simple-to-medium complex components.

- High-precision WEDM features advanced CNC systems and ultra-stable wire tension control, achieving micron-level accuracy ideal for aerospace, medical, and precision mold components.

2. By Wire Movement Mode: NC WEDM & Wire Electrical Discharge Machining with Recycle (WEDM-R)

- NC WEDM uses disposable brass or copper wire, which moves continuously and is discarded after use, ensuring consistent cutting performance for large-scale machining.

- WEDM-R adopts a wire recycling system to reuse the electrode wire, reducing material costs while maintaining good precision for small-batch, cost-sensitive projects.

3. By Dielectric Fluid Type: Water-Based WEDM & Oil-Based WEDM

- Water-based WEDM utilizes deionized water as dielectric fluid, offering fast cooling, efficient debris clean-up, and is the most common choice for most conductive metal machining.

- Oil-based WEDM uses insulating oil, delivering better surface finish and less electrode wear, suitable for processing extremely hard materials like tungsten carbide.

Typical Components & Application Industries of WEDM

1. Typical Precision Components

- Mold & die parts: Core pins, cavity inserts, die-casting molds, and progressive stamping dies with complex contours.

- Aerospace parts: Turbine blade cooling holes, engine nozzle components, and lightweight structural brackets.

- Medical devices: Surgical instrument blades, orthopedic implant components, and micro-drill bits for dental tools.

- Precision machinery parts: Gear teeth, splines, and micro-slots for high-precision measuring equipment.

2. Key Application Industries

- Mold & Die Manufacturing: The most dominant application, enabling the fabrication of intricate mold geometries that are hard to machine via conventional methods.

- Aerospace & Defense: Producing high-strength, heat-resistant alloy components with strict tolerance requirements.

- Medical Device Manufacturing: Crafting biocompatible metal parts with micro-level precision for surgical tools and implants.

- Electronics & Semiconductor: Manufacturing precision lead frames, connector pins, and micro-electrode components.

- Automotive Industry: Machining fuel injector nozzles, transmission gears, and sensor components for high-performance vehicles.

Materials Suitable for WEDM Processing

1. High-Strength Alloy Steels

Tool steel, die steel, high-speed steel (HSS): Ideal for mold/die components requiring wear resistance and hardness; ensures long service life for stamping, injection molding dies.

2. Heat-Resistant Superalloys

Titanium alloys, nickel-based alloys (e.g., Inconel, Hastelloy): Used in aerospace engine parts and high-temperature components; withstands extreme thermal and mechanical stress.

3. Hardened Metals & Composites

Carbide, cermet, sintered metal composites: Suited for cutting tools and precision mechanical parts; maintains structural integrity even under high-load machining scenarios.

4. Conductive Non-Ferrous Metals

Copper, brass, aluminum alloys: Applied in electrical components and lightweight structural parts with complex shapes; enables fast, precise cutting without material deformation.

5. Special Conductive Materials

Magnesium alloys, zinc alloys: Suitable for lightweight automotive and electronic components; compatible with WEDM’s non-contact machining to avoid cracking of brittle castings.

Surface Treatment Processes for WEDM Products

1. Surface Smoothing & Defect Removal

- Deburring & Polishing: Manual polishing, ultrasonic polishing, or abrasive flow machining (AFM) to remove recast layers and micro-burrs, enhancing surface smoothness for precision components.

- Chemical Etching: Eliminates the heat-affected zone (HAZ) on the workpiece surface, improving corrosion resistance and surface uniformity for mold and aerospace parts.

2. Strengthening & Protective Coating

- Electroplating & PVD Coating: Electroplating (nickel, chromium) or PVD coating (titanium nitride) to add a protective layer, boosting wear resistance and extending the service life of tools and mechanical parts.

- Anodizing: Applicable to aluminum, titanium, and magnesium alloys; forms a dense, wear-resistant oxide film, improving corrosion resistance and enabling customizable coloring for aesthetic and functional needs.

3. Stress Relief & Dimensional Stability

- Heat Treatment: Low-temperature annealing to relieve residual machining stress, preventing deformation and ensuring dimensional stability of high-precision alloy components.

Check Out the ToolkitWEDM Frequently Asked Questions (FAQs)

What is the minimum thickness of parts that WEDM can process?

expand_less expand_moreA: WEDM can handle parts as thin as 0.1 mm and as thick as 500 mm, depending on the machine configuration and workpiece material.

Can WEDM machine non-conductive materials?

expand_less expand_moreA: No, WEDM relies on electrical spark erosion, so it only works with conductive materials like metals and metal composites.

How to improve the surface finish of WEDM parts?

expand_less expand_moreA:Optimize machining parameters (lower discharge energy, slower wire speed) and apply post-processing such as ultrasonic polishing or chemical etching.

What is the typical tolerance of WEDM processing?

expand_less expand_moreA: High-precision WEDM achieves a tolerance of ±0.001–±0.005 mm, suitable for aerospace, medical, and precision mold components.

Does WEDM cause workpiece deformation?

expand_less expand_moreA: Minimal deformation occurs because WEDM is a non-contact process with no cutting force; low-temperature annealing post-processing can further eliminate residual stress.