Assembly Services

* Precision assembly, one-stop solution, ISO-certified quality.

* ±0.005mm accuracy, flexible production, on-time delivery.

* Component to complete machine assembly, reliable support for your projects

ISO 9001:2015

Anxin Precision Assembly Services Flow

Advantages of Choosing Anxin for Precision Assembly

1. Unmatched Precision & Quality

Achieve ±0.005mm assembly accuracy with ISO/IATF-certified quality control systems; full-process inspection (IQC/IPQC/FQC) ensures 99.8% product qualification rate.

2. One-stop Integrated Solution

Seamlessly combine CNC machining, surface treatment and assembly services, eliminating multi-vendor coordination costs and shortening project lead time.

3. Flexible Production Capacity

Support small-batch trial runs (1–50 units) to large-scale mass production (10,000+ units) with customized production plans for diverse order demands.

4. Reliable Delivery & Support

Ensure on-time delivery with efficient production scheduling; provide professional after-sales technical support for assembly process optimization and troubleshooting.

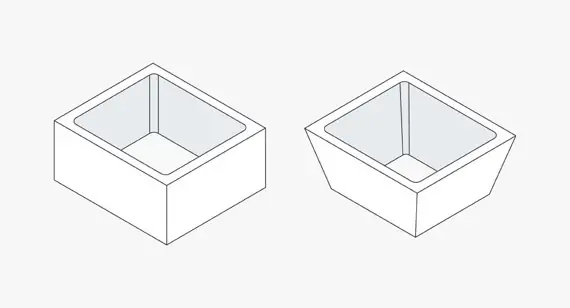

Precision Assembly Methods for Anxin’s Services

1. Automated Flexible Assembly

Adopt servo press-fitting machines and vision alignment systems for high-precision, high-efficiency assembly of standardized components and modules, suitable for large-scale production.

2. Manual Precision Assembly

Deploy skilled technicians with specialized tools for micro-components and custom non-standard parts, ensuring ±0.005mm accuracy for small-batch, high-complexity projects.

3. Modular Integration Assembly

Pre-assemble sub-modules (e.g., mechanical, electrical units) separately, then integrate into finished products; this method shortens lead time and simplifies maintenance.

Check Out the Toolkit

Industries Served by Assembly Services

1. Automotive Manufacturing

Precision assembly of engine parts, chassis structural components, and transmission assemblies for OEMs and auto parts suppliers.

2. Industrial Automation

Assembly of industrial robot joint modules, automated production line fixtures, servo motor components, and precision transmission mechanisms.

3. Medical Devices

Cleanroom assembly of medical testing equipment cores, surgical instrument components, and rehabilitation device mechanical structures, compliant with medical industry standards.

4. Aerospace

Assembly of aerospace precision components and aerospace instrument structural parts, meeting strict requirements for high reliability and precision.

5. Electronic Equipment

Assembly of metal housing modules for electronic devices, precision connector components, and transmission structures for smart equipment.

6. New Energy

Assembly of new energy vehicle battery structural parts, charging pile core components, and photovoltaic equipment bracket assemblies.

Check Out the Toolkit

Precision Assembly Services - FAQs

What assembly accuracy can you achieve?

expand_less expand_moreA: We guarantee ±0.005mm assembly accuracy, compliant with ISO 9001 and IATF 16949 standards.

Can you handle both small and large batch orders?

expand_less expand_moreA: Yes, we support flexible production from small-batch trials (1–50 units) to large-scale mass production (10,000+ units).

Do you provide one-stop solutions?

expand_less expand_moreA: Absolutely. We integrate CNC machining, surface treatment, assembly and quality testing for end-to-end service.

What industries do you serve?

expand_less expand_moreA: Our services cover automotive, industrial automation, medical devices, aerospace, electronics and new energy sectors.

What after-sales support do you offer?

expand_less expand_moreA: We provide technical support for process optimization, product troubleshooting and maintenance guidance.