Custom 3D Printing Services

The First Lesson of 3D Printing for the Curious: How Does It Turn "Virtual" into "Reality"?

Breaking down complex 3D objects into simple 2D layers and precisely reconstructing them through material accumulation is the core principle. What makes this revolutionary is its ability to create a super-short chain from design to physical reality, enabling personalized customization and the fabrication of intricate internal structures—capabilities that traditional manufacturing methods can hardly achieve.

Certifications ISO 9001:2015

Core Definition: What is 3D Printing?

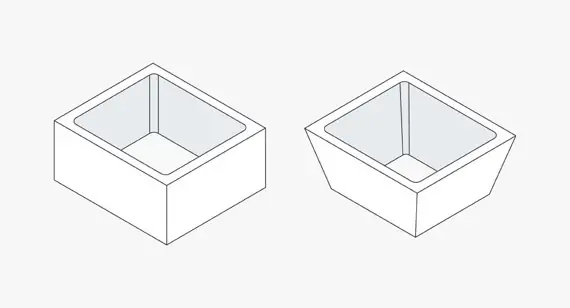

3D printing, also known as additive manufacturing, is a transformative technology that creates three-dimensional objects by sequentially layering materials based on a digital model. Unlike traditional subtractive manufacturing (cutting away material) or formative manufacturing (molding), it enables a direct transition from "design to physical object."

How It Works: Three Steps to Creation

1. 3D Modeling

Digital models are created using CAD software or 3D scanning (common formats: .STL, .OBJ).

2. Slicing

Specialized software horizontally slices the model into hundreds to thousands of two-dimensional cross-sections, generating machine-readable instruction codes (G-code).

3. Layer-by-Layer Printing

The printer follows the instructions to add materials layer by layer using specific technologies, ultimately stacking them into the final shape.

Technology Trends

1. Multi-Material Hybrid Printing

Enables integrated manufacturing of hard-soft combinations and gradient materials.

2. Large-Format High-Speed Printing

Advancements in construction 3D printing speed, with maximum print sizes exceeding 30 meters.

3. Intelligent Integration

AI-driven generative design, real-time print monitoring, and automated post-processing pipelines.

4. Sustainable Development

Recyclable materials, energy-efficient processes, and remanufacturing of used parts.

3D printing represents not only a revolution in manufacturing technology but also a comprehensive transformation of design thinking, business models, and supply chain systems. It is evolving from a "rapid prototyping tool" into a "means of end-use product manufacturing," driven by both personalized consumption and intelligent manufacturing, continuously expanding the boundaries of human production.

Core Advantages and Value of 3D Printing

Design Freedom

Enables the production of complex structures that are impossible with traditional processes, such as topology-optimized designs, internal flow channels, and lattice structures.

Rapid Iteration

Transforms designs into physical objects in just hours to days, accelerating R&D cycles by up to 70%.

Personalized Customization

Achieves "one-piece ordering" with minimal cost variation, ideal for medical implants and customized products.

Supply Chain Simplification

Supports distributed manufacturing and on-demand production, reducing reliance on inventory and logistics.

The Core Techniques of 3D printing

1. Before Printing: Model and Slicing Preparation

1.1-Model Check: Ensure the model is "watertight" (no holes or gaps) and use software for automatic repair if needed.

1.2-Optimal Orientation:

Place stress-bearing or smooth surfaces facing down or on their side.

Minimize overhangs to save support material.

1.3-Key Slicing Parameters:

Layer Height: Use 0.1–0.15mm for detail, 0.2–0.28mm for speed.

Infill Density: 15%–25% for general parts, 50%–80% for load-bearing parts.

Print Speed: Outer walls slow (30–50mm/s), infill faster (60–80mm/s).

Supports: Add when overhang angle >45°; prefer "tree supports" to save material.

2. During Printing: Machine and Material Control

2.1-Bed Leveling: The first critical step—ensure the nozzle height is even (slight resistance when sliding a piece of paper).

2.2-Temperature Control:

Nozzle: PLA at 190–220°C, ABS at 230–250°C.

Heated Bed: PLA at 50–60°C to prevent warping, ABS at 80–110°C.

2.3-Material Drying: Dry hygroscopic materials like nylon or PETG in a filament dryer before printing.

3. After Printing: Post-Processing and Improvement

Careful Support Removal: Use flush cutters and trim patiently from the base.

Surface Finishing: Sand and polish PLA; smooth ABS with acetone vapor.

Strength Enhancement: For load-bearing parts, increase nozzle temperature by 5–10°C or reduce print speed to improve layer adhesion.

4. Three Golden Rules

The First Layer Determines Success: Prioritize slow and precise first-layer adhesion.

Cooling in Moderation: Use fans for small PLA parts; turn them off for large ABS prints to prevent cracking.

Change One Parameter at a Time: When troubleshooting issues (e.g., stringing, layer lines), adjust only one variable per test.

Applications: Which Fields Is It Transforming?

1. Medical (Personalized & Precise)

Surgical guides, orthopedic implants, dental restorations

Bioprinting, tissue engineering scaffolds

Personalized medical devices

Preoperative planning: Printing patient organ models allows doctors to simulate surgery on a "replica."

Orthopedics & dentistry: Creating perfectly fitted titanium alloy bone implants, clear aligners.

Rehabilitation aids: Rapid customization of low-cost, fully body-conforming orthoses.

2. Manufacturing & Prototyping (Speed & Innovation)

Rapid prototyping: Turning design concepts into testable physical objects within days, accelerating product development.

Customized tooling: Manufacturing unique jigs, fixtures, and tools for production lines.

Small-batch production: Directly printing end-use parts, especially suitable for niche, discontinued, or complex structural components.

3. Cultural Creation & Education (Creativity & Tangibility)

Creative design & art: Producing complex sculptures and personalized accessories that traditional techniques cannot achieve.

Educational models: Transforming abstract concepts like molecular structures, historical artifacts, and geographical terrains into tactile teaching aids.

4. Frontier Exploration (Futuristic)

Complex flow channels, integrated structures

Conformal cooling, lattice structures

High-temperature alloy components

Aerospace: Printing lighter, stronger rocket engine components.

Architecture: Experimenting with concrete-based monolithic printing of building structures.

Food & bioprinting: Exploring chocolate printing and even cellular tissue printing.

Check Out the Toolkit

Material Selection on 3D Printing

1. Plastics (Most Common)

PLA

Eco-friendly, easy to print, relatively brittle.

Suitable for: display models, educational tools.

ABS

Good strength, heat-resistant, but prone to shrinkage.

Suitable for: functional prototypes, enclosures.

PETG

Combines strength and toughness, chemical-resistant, food-safe.

Suitable for: containers, protective covers.

Nylon

High strength, wear-resistant (requires moisture protection).

Suitable for: gears, tools.

TPU (Flexible)

Excellent elasticity, impact-resistant.

Suitable for: gaskets, wearable devices.

2. Resins (High Precision)

Standard resin: Excellent detail, suitable for fine models.

Tough resin: Resistant to fracture, suitable for snap-fit parts.

High-temperature resin: Withstands 200°C+, suitable for prototypes of heat-generating components.

Dental/medical resin: Biocompatible, suitable for dental models, surgical guides.

3. Metals (Industrial Grade)

Stainless steel: Corrosion-resistant, used for parts, medical screws.

Titanium alloy: Lightweight and strong, used for aerospace components, artificial joints.

Aluminum alloy: Lightweight, good heat dissipation, used for automotive parts, drones.

High-temperature alloys: Withstand 850°C+, used for rocket engines.

4. Specialized Materials

Ceramics: High-temperature insulators, dental restorations.

Carbon fiber reinforced: Extremely light and strong, used for race cars, drones.

Concrete: Architectural structure printing.

Biomaterials: Hydrogels (tissue engineering), PEEK (advanced implants).

When selecting 3D printing materials, always consider three dimensions: requirements (strength/precision/heat resistance), process (printer compatibility), and cost.

Surface Treatment Options for 3D Printing

I. Essential Post-Processing (Required for all parts)

Support Removal: Carefully remove supports using flush cutters.

Surface Cleaning: Blow away powder, brush off debris; wash resin parts in alcohol.

II. Four Main Finishing & Enhancement Methods

Method A: Sanding & Polishing (Most Versatile)

Process: Sand progressively from coarse to fine grit sandpaper (e.g., 240 → 800 → 2000 grit), then polish with compound or a buffing wheel.

Result: Eliminates layer lines for a smooth finish.

Best for: Nearly all materials (plastics, resins, metals).

Method B: Chemical Smoothing (For ABS, etc.)

Process: Expose ABS parts to acetone vapor (requires proper ventilation setup).

Result: Instantly dissolves layer lines for a glossy, smooth surface.

Note: Only works on specific materials; involves safety risks.

Method C: Painting (For Best Aesthetics)

Process: Sand surface → apply filler primer (fills minor imperfections) → apply base coat → apply top coat → apply clear coat.

Result: Achieves any color and texture (matte, metallic, fluorescent).

Key Step: The filler primer is crucial for a perfect finish.

Method D: Professional Finishing (Industrial Grade)

Sandblasting: Blasts the surface with high-speed particles for a uniform, fine matte texture. Ideal for nylon, metal, resin.

Electroplating: Deposits a layer of real metal (e.g., chrome, gold) for metallic shine and increased hardness. Requires conductive pre-treatment.

Heat Treatment: Baking in an oven (e.g., PLA at 60°C) can increase strength and relieve internal stresses.

III. Quick Selection Guide by Material

PLA/ABS/PETG (FDM Plastic):

Basic: Sanding + Painting.

Advanced: ABS can be chemically smoothed with acetone; PLA can be heat-treated for strength.

Resin (SLA/DLP):

Basic: Alcohol wash + UV curing.

Refined: Wet sanding → polishing → spray painting with model paints.

Nylon (SLS):

Standard: Sandblasting for a premium matte finish.

Coloring: Can be dyed with specialized dyes.

Metal:

Essential: Sandblasting or electropolishing for deburring and shine.

Coloring: Anodizing (for aluminum/titanium) adds color and enhances the surface.

Check Out the Toolkit

3D Printing Frequently Asked Questions (FAQs)

What is 3D printing?

expand_less expand_moreA: A manufacturing process that builds physical objects layer by layer from digital designs using materials like plastic, resin, or metal.

What can 3D printing create?

expand_less expand_moreA: It can produce everything from custom jewelry and prototypes to functional aerospace parts, excelling in complex geometries and small-batch production.

What materials are commonly used in 3D printing?

expand_less expand_moreA: Plastics (PLA, ABS), resins, nylon, and industrial metals like titanium and stainless steel.

Is 3D printing expensive?

expand_less expand_moreA: Desktop printers are affordable (from ~$200), while industrial systems and metal printing remain costly.

How fast is 3D printing?

expand_less expand_moreA: Speed varies—small models take hours, larger/complex designs may require days.

How accurate is 3D printing?

expand_less expand_moreA: Desktop: ~0.1–0.3 mm; industrial: as fine as 0.025 mm (e.g., dental models).

What are the drawbacks of 3D printing?

expand_less expand_moreA: High per-unit cost for mass production, material strength constraints, and often manual post-processing.

What software is needed for 3D printing?

expand_less expand_moreA: Modeling software (Fusion 360, Blender) and slicing software (Cura, PrusaSlicer). Beginners can start with Tinkercad.

How is 3D printing used in healthcare?

expand_less expand_moreA: For personalized medical devices like surgical guides, bone implants, and dental aligners.

What are future trends in 3D printing?

expand_less expand_moreA: Trends include multi-material printing, automation, large-scale construction, and bioprinting of tissues.